Many of our customers often have such a question: Stainless Steel 441 vs 316 - Hver er munurinn? Today, we delve into a comparison between the two popular stainless steel grades: 441 and 316. Understanding the distinct features and applications of these alloys is crucial for making informed decisions in a range of industries.

Ryðfrítt stál 441 vs 316 - Hver er munurinn?

Ryðfrítt stál 441 vs 316 – 1. Skilgreining

Ryðfrítt stál 441

Stainless Steel 441 belongs to the family of martensitic ryðfríu stáli. Það er króm-based alloy that offers excellent corrosion resistance, particularly in oxidizing environments. This grade is often chosen for its cost-effective alternative to other stainless steel grades, while maintaining good mechanical properties.

Ryðfrítt stál 316

Stainless Steel 316 is an austenítískt ryðfrítt stál grade that is widely used due to its excellent corrosion resistance and mechanical properties. The addition of mólýbden in 316 stainless steel enhances its resistance to pitting and crevice corrosion, particularly in chloride-containing environments.

Stainless Steel 441 vs 316 – 2. Key Features

Key Features of Stainless Steel 441:

- Samsetning: 441 stainless steel is primarily composed of chromium, with a small amount of carbon. This composition gives it its corrosion-resistant properties.

- Tæringarþol: 441 stainless steel exhibits good resistance to corrosion in oxidizing environments, such as boiling water and steam. However, it may not perform as well in reducing environments.

- Seguleiginleikar: Being a martensitic steel, 441 is magnetic. This feature can be advantageous in applications where magnetism is desired.

- Styrkur og sveigjanleiki: 441 stainless steel offers good strength and ductility, making it suitable for a wide range of applications.

- Suðuhæfni: This grade can be welded using common welding techniques, but post-weld annealing may be required to ensure optimal corrosion resistance.

Key Features of Stainless Steel 316:

- Samsetning: 316 stainless steel contains chromium, nickel, and molybdenum. The combination of these elements gives it its superior corrosion resistance.

- Tæringarþol: 316 stainless steel offers exceptional resistance to corrosion, especially in chloride-containing environments such as saltwater. It performs well in both oxidizing and reducing environments.

- Ekki segulmagnaðir eiginleikar: Austenitic stainless steel grades, including 316, are non-magnetic in their annealed condition. This property is suitable for applications where magnetism is not desired.

- Styrkur og hörku: 316 stainless steel has good strength and toughness, making it suitable for high-stress applications.

- Suðuhæfni: This grade is easily welded using various welding techniques and does not require post-weld annealing.

Ryðfrítt stál 441 vs 316 – 3. Umsóknir

Applications of Stainless Steel 441:

- Íhlutir í bifreiðum

- Hitaskipti

- Skrautlegur vélbúnaður

- Skurðaðgerðir

Applications of Stainless Steel 316:

- Sjóbúnaður

- Efnavinnslubúnaður

- Skurðaðgerðir

- Matur vinnsla búnaður

Stainless Steel 441 vs 316 – 4. Comparison

When comparing Stainless Steel 441 and 316, several key differences emerge:

- Tæringarþol: While both grades offer good corrosion resistance, 316 stainless steel, with its molybdenum content, performs better in chloride-containing environments. 441 stainless steel excels in oxidizing environments.

- Seguleiginleikar: 441 stainless steel is magnetic, while 316 stainless steel is non-magnetic. This difference is crucial in applications where magnetism affects performance or functionality.

- Kostnaður: Generally, 316 stainless steel costs more than 441 due to its superior corrosion resistance and wider range of applications.

- Forrit: Both grades have their unique applications. 441 stainless steel is commonly used in automotive and heat exchanger applications, while 316 stainless steel finds use in marine, chemical processing, and surgical applications.

Niðurstaða

In summary, Stainless Steel 441 and 316 both have their strengths and applications. 441 stainless steel offers good corrosion resistance in oxidizing environments, is magnetic, and costs less. On the other hand, 316 stainless steel, with its molybdenum content, provides superior corrosion resistance in chloride-containing environments, is non-magnetic, and costs more.

Þakka þér fyrir að lesa greinina okkar og við vonum að hún geti hjálpað þér að öðlast betri skilning á muninum á Ryðfríu stáli 441 vs 316. Ef þú ert að leita að Ryðfríu stáli 441 & 316 birgjum á netinu núna skaltu ekki hika við að hafa samband við Sino ryðfríu stáli.

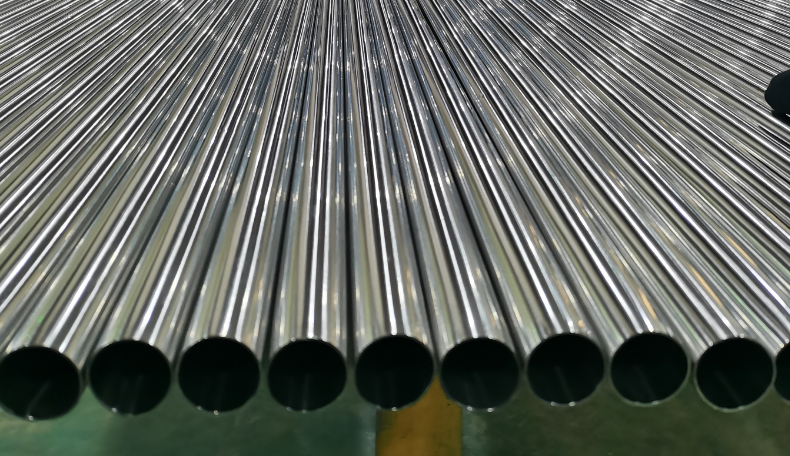

Sem leiðandi birgir ryðfríu stáli vara frá Shanghai Kína, veitir Sino Stainless Steel viðskiptavinum hágæða ryðfríu stáli plötur, ryðfríu stáli rör, ryðfríu stáli rör, ryðfríu stáli ræmur, ryðfríu stáli vafningum, ryðfríu stáli plötumog ryðfríu stáli stangir á mjög samkeppnishæfu verði.

: +86-18621535697

: +86-18621535697  : export81@huaxia-intl.com

: export81@huaxia-intl.com